Victory Packaging offers case packers and case machines to optimize your production line's efficiency. Case packing equipment of years past lacked the ability to meet the growing demands of today's production lines. Today's businesses need fully-automated case packing equipment to streamline their production lines.

Modern case packing equipment is one of the best investments to accelerate business growth. Our case packing equipment is designed to surpass the packaging industry's expectations, while our expertise and industry knowledge improves your standing among your competition. We'll guide you every step of the way with reliable 24/7 support to help streamline your production processes and significantly reduce downtime.

Case Packing Equipment + Support

Fully-automatic case packing equipment can be a game-changer for your business. With the specialists to guide your buying decisions, we carefully consider how your business operates in order to select the appropriate case packing equipment to meet your needs. Count on our case packing equipment expertise with 24/7 support to be there when you need us most.

Case Packing Equipment Models

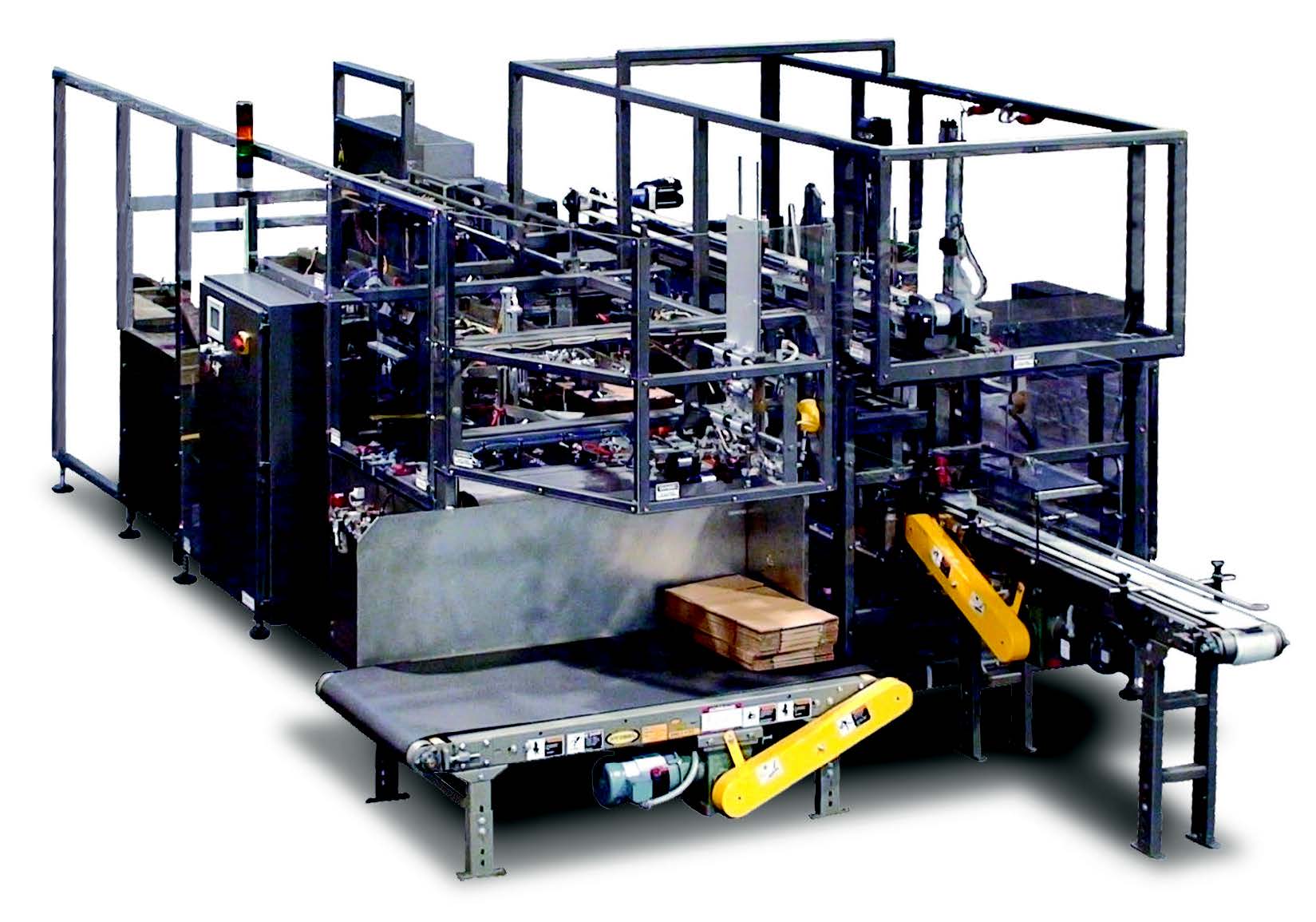

Packomatic® Case Packers

Package more with less -- less operator labor and less corrugated fiber. Whatever your product, WestRock makes the case packer that packs faster at a lower, overall cost. Our case packers are designed to run today’s lighter weight materials, including high recycled content, while speeding up your line and focusing operator attention on the part that matters most – your product as it goes into the case. Ergonomic design makes it easier for operators to maintain a high level of productivity. The systems’ versatility easily accommodates a wide variety of products and packaging configurations.

|

Rap-A-Mat® Wraparound Case Packers

The Rap-A-Mat Wraparounds collate products directly from the packaging line for small to large applications. The speeds vary from 12 to 25 (semi to fully automatic speeds) cycles per minute, depending on the equipment and enable size change-overs in less than 15 minutes.

|