Meta® 150 Case Former

The unique, precision mandrel-forming case technology from our Meta® 150 offers the ultimate in equipment flexibility and speed. Die cut blanks are precisely formed into cases around a fixed mandrel, minimizing case skew and maximizing structural integrity. This precision enables better box performance on your production line and through your distribution system. No longer limited to just ordinary four-sided cases, you now have the capability to run three, four, five, six, seven or eight-sided cases. The forming methodology also allows quick changeover between box sizes, and minimal or no changeover required between boxes sizes with similar footprints.

|

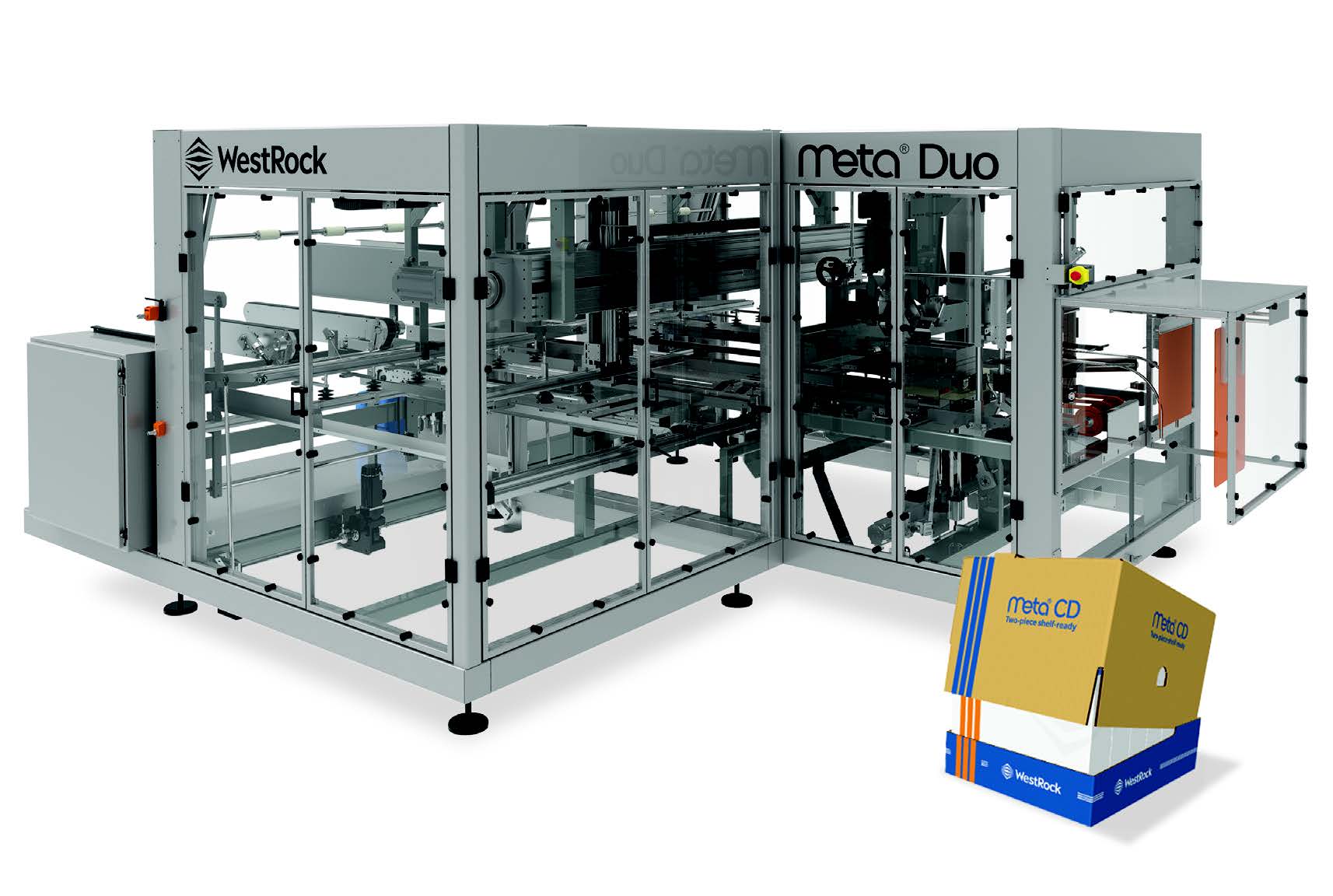

Meta® Duo Case Former

Offering true multi-channel, in-house automation, Meta Duo efficiently transitions between 4-sided, 8-sided, HSCs, one and two-piece SRP designs and SIOCs, helping you meet various retailer and e-tailer requirements from a single, small footprint machine.

|

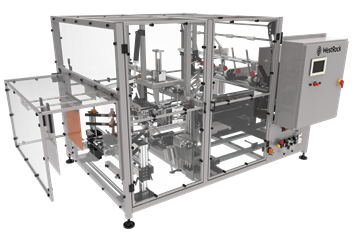

Meta® LS (Low Speed) Case Former

The unique, precision mandrel-forming case technology from our Meta® LS case former is specifically engineered to meet the demands of your production operations. Die cut blanks are precisely formed into cases around a fixed mandrel, minimizing case skew and maximizing structural integrity. This precision enables better box performance on your production line and through your distribution system. No longer limited to just ordinary four-sided cases, you now have the capability to run three-, four-, five-, six-, seven- or eight-sided cases. The forming methodology also allows quick changeover between box sizes, and minimal or no changeover required between box sizes with similar footprints.

|